The tunnel segment is at the heart of the expertise offered by CBE Group. The company designs and manufactures moulds for the production of those segments, as well as automated plants aimed at increasing their production rate.

How do you dig a tunnel ?

In a tunnel digging project, the length or the type of ground often require the intervention of a tunnel boring machine (TBM). The TBM allows the creation of the tunnel by digging directly into the rock. While digging, the TBM also installs the precast segments in place, so that they form the coating of the tunnel.

The TBM digs into the rock using its cutting head

Inside the TBM, the segments are stored and then placed on the wall by an erector.

Key data about TBMs:

- They cover 10 to 30 meters per day, depending on the type of ground

- The tunnels can have a diameter that goes from 3 to 20 meters

The ring and its moulds

The segments put on the rock wall are joined together in order to form a concrete ring. They have several roles within the tunnel:

- Finishing up the internal wall of the gallery

- Ensuring that the gallery will be resilient enough faced to external pressure

- Allowing the TBM to move forward, as the machine leans upon the last ring it installed to progress inside the tunnel.

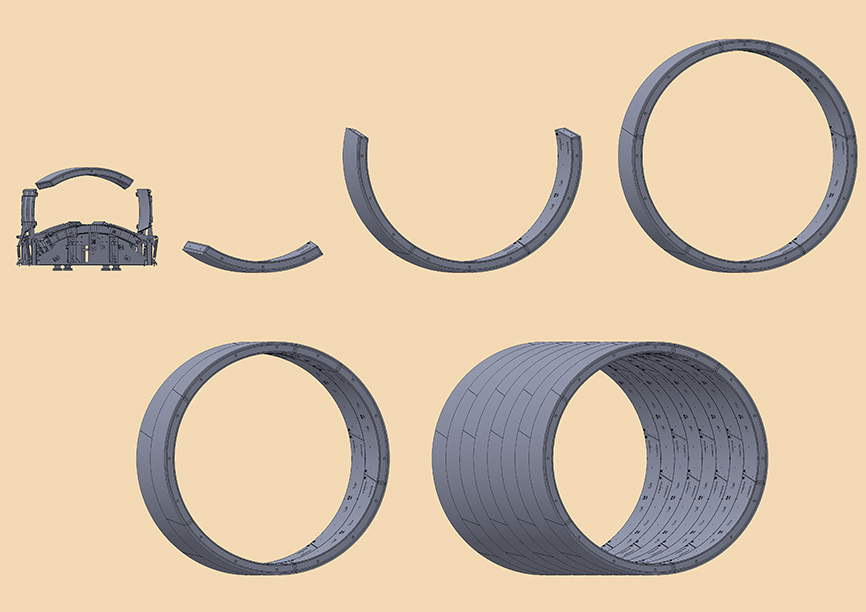

From the CBE Group mould (from which each segment is casted) to the concrete ring (which succession will form the coating of the tunnel)

The concrete ring is usually composed of a variable number of segments (from 4 to 10), depending on the tunnel geometry and constraints:

- Standards segments, which compose the main part of the ring

- Two counter-key segments

- A key segment, a smaller segment which closes the ring

As a consequence, several moulds are needed to create a complete ring. All the moulds needed to compose one ring form a set of moulds.

The ring has to fit perfectly into the tunnel, which implies that each mould must be extremely precise, as each segment is to fit perfectly into the ring. CBE Group guarantees a precision of a three tenth of a millimeter.

The concrete segment also has extensions which are necessary for the installation and assembly of each segment. Those crucial elements are directly integrated within CBE Group moulds.

The role of segments is crucial in a tunnel. CBE Group offers its expertise and experience in order to provide its clients with the most effective moulds.

CBE Group, tunnelling expert, offers you tailor-made solutions for the optimization of your project.

Please contact us or ask us directly for a quote.